JESUS IS COMING SOON!

Our Barn Construction Process

Why Choose Bald Eagle Barns?

Barn Eagle Barns is committed to giving you the best quality product out there! We want to offer you old-fashioned quality, hometown service, and unbeatable value. That’s why we build our barns, cabins, garages, and other buildings with high-quality materials. Our barn construction process involves standard procedures that set them apart from other buildings.

Pressure Treated Skids

We start our barn construction with a solid base. 5 pressure-treated 4×4 skids run the full length of the building. Our smaller, 8-foot wide sheds are outfitted with 3 skids. This standard feature gives you maximum support for the foundation of your building. Without sufficient durability in the foundation, the roof of your building will eventually sag. Our exclusive 5-skid design ensures that the walls are straight and the roof line level for the lifetime of the building!

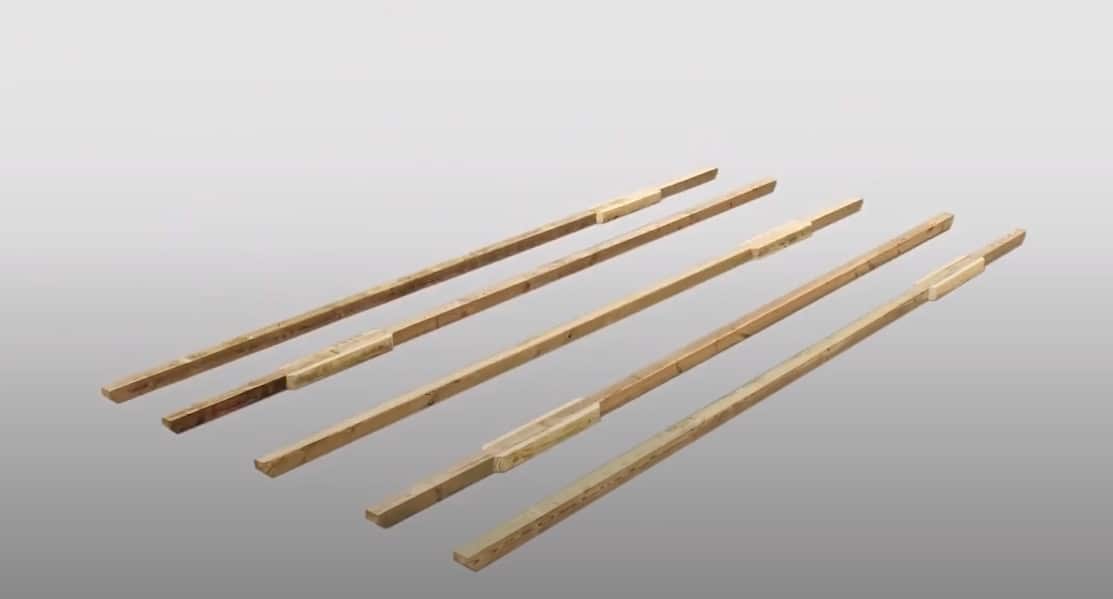

Floor Joists

Because we understand your needs and wants, we’ve committed ourselves to ensuring that our buildings will stand the test of time. Knowing that the floor of your building is solid will give you peace of mind. Our buildings come standard with pressure-treated 2×6 floor joists spaced every 16 inches on-center. Our 8-foot wide sheds have pressure-treated 2×4 floor joists spaced at the same distance. All garage models come standard with pressure-treated 2×6 floor joists spaced 12 inches on-center for even more durable flooring for the extra weight of a vehicle. With these floor joists spanning the length of the 5 base skids, you’re given the strongest floor available on the market.

Fastening the Flooring

Next in our barn construction process is focusing on the fastening of our flooring. Not only is the construction of the joists and skids important but it’s also important how they are fastened together. We show our commitment to bringing you the strongest shed floor with the 8-inch screws that fasten the floor joists to the skids. One our 8-foot wide sheds, we use 6-inch screws. Using powerful electric drills, we drive these long screws all the way down through the floor joists and into the skids. We use a unique combination of treated ring shank nails and long 8-inch screws to bring you the toughest, strongest, and most durable floor system in the industry!

Flooring

After the foundation is securely fastened in place, we outfit the floor with world-famous Advantech flooring. This flooring has become famous for its waterproof durability and is being used all over the country and the #1 flooring product in the housing market! The impressive durability and longevity of this flooring is what makes Advantech stand above its plywood predecessor. While plywood is prone to delaminate and fall apart over time, Advantech remains strong thanks to its structural orientation and the water-resistant glue found throughout the entire panel. Another great advantage of this standard feature is that it’s tongue and groove. This makes for a stronger and quieter floor.

Standard Roof Construction

No one likes when the roof of their building gets damaged or comes down. To ensure that you are protected from mayhem, we install a set of double 2.5×4-inch steel plates as a standard part of our barn construction. These connect the truss joints. These two plates are pressed together with 5 tons of tremendous force. We use larger plates than most manufacturers to provide you with the strongest roof system.

We also equip our buildings with expansion joints in the roof decking. Seasons and temperatures change and your barn will change with them. Wood swells and contracts in different weather conditions, so we leave a small space for the wood to do this without buckling your roof.

Caulking

After the LP siding has been successfully installed, the next step is caulking every nail head. We do this manually to ensure it’s done well. We also caulk every siding joint and trim corner. This process helps to seal the exterior, providing a more clean, durable, and aesthetically pleasing finish. This may seem like a small thing in the barn construction process, but it’s an important one! This step does not apply to buildings with a urethane finish.

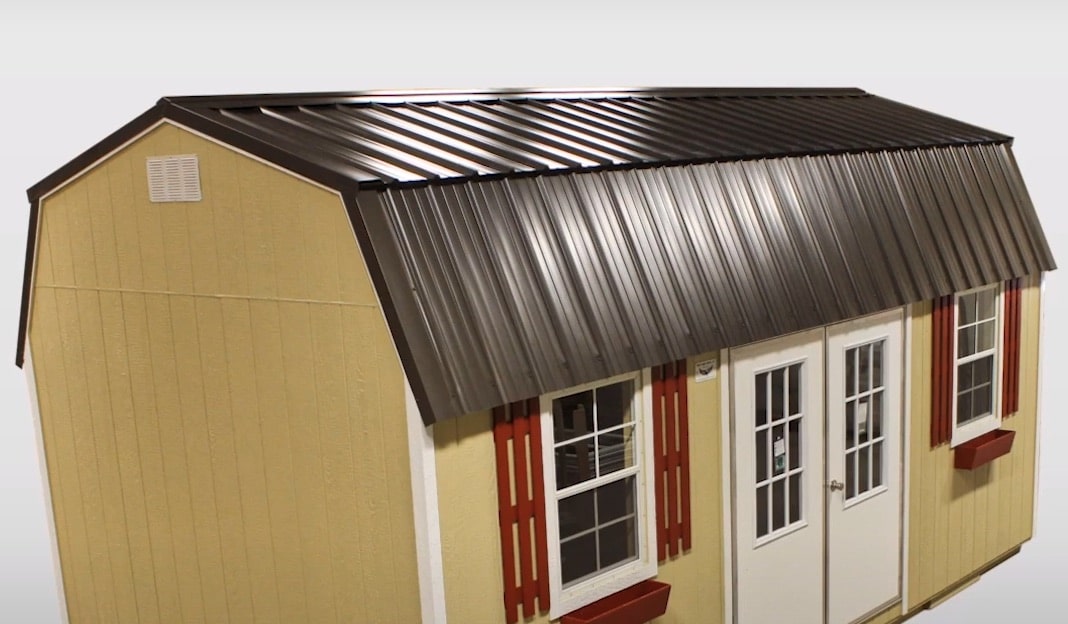

Roofing

The roof of your building does more than just look good! It serves as the barrier between the harsh elements and your valuables. Because this is such a crucial part of the construction of the building, we provide you with a roof you can trust. We use energy-efficient, 40-year metal roofing as a standard feature. Below the metal, we install solid wood decking to ensure your building will not sweat or gather condensation. You can also add the custom option of a radiant barrier to keep your building at a more consistent temperature. This also provides a stronger roof system. We also offer 30-year Architectural Shingles if you prefer them. The addition of shingles is $300.

Vent

Just like you, your building needs to breathe. It is crucial that your storage building gets fresh air through the interior space. This is why we install a standard 8×16-inch vent in each gable end of your building. These two vents allow air to enter and exit the building which helps with several things. First, it helps your building stay cooler and at a more consistent temperature. Vents also help keep fresh air inside your building. Last, but not least, vents help prevent mold and mildew from growing inside your building. Keeping your building breathing is imperative to a long life!

Security of Your Building

When it comes to security, we have it locked in! The standard doorknobs we use in our barn construction process turn easily, close tightly, and lock securely to provide you with a handy and secure place to store your valuables. Each door comes with 2 keys and each knob is keyed separately for your protection.

Keeping moisture, bugs, and rodents out of your building is one of our top priorities. Few things do this better than the double rubber seal which is installed all the way around the door frame. This keeps your valuables securely stored behind a sealed door.

Our unique security chain and spring system protect your door while opening and closing on windy days. This chain and spring keep your door in tip-top shape for years to come! Check out our door upgrades for more options!

Trust our Barn Construction Process

When you see the Bald Eagle Barns nameplate on a building, you know the building has been built with high-quality standard features that set the building apart from the rest. Each building we produce comes with this factory identity sign. With this sign on your building, you can rest in the fact that your building is safe, secure, and structurally sound. We have followed our standard barn construction process for your building, so your Bald Eagle barn will add durability, stability, and simplicity to your life! If you want to go even a step further, check out our custom options that take your building to another level. Contact us today to get started on your new building!